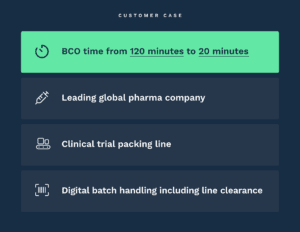

Ready for the next batch faster

- Reduce inspection time by up to 75%.

- Digital compliance documentation always ready for audit.

- Based on fully validated GAMP Cat. 4 software

- ROI in days. Yes, days.

Line clearance eats production time. But it does not have to.

While operators manually check the line for rogue components and go through detailed SOP's and checklists to document that the line has been properly cleared, the clock is ticking.

Often well past the 60-minute mark.

And with a future of smaller batches and multiple daily BCOs, reducing the time to next batch is a key priority.

Automated line clearance for world-class OEE

An automated line clearance system based on machine vision completes inspections quickly, consistently and repeatably.

The outcome?

Improved line availability and higher throughput – perhaps even to the extend where new line investments can be postponed.

Significant OEE improvements mean that the average ROI is counted in days.

Know with certainty. And document it.

Reduce risk by not relying on the human eye and meet auditors’ demands at any time with easily located and comprehensive documentation that details exactly what has happened, which actions were taken and by whom.

- Creates a full clearance report once the line is cleared

- Reports and images are timestamped and easy to find

- Built-in audit trail and compliance management

- Tracks both users and line clearance activities

- Report log file for all previous clearance activities

Ready for the next batch in 3 simple steps

No more spending massive amounts of time on paperwork. Less bending out of shape to check hard-to-reach areas for rogue components.

- Start the camera-assisted line clearance process.

- Remove rogue components from the clearly highlighted areas of concern.

- Mark the issue as resolved for the system to grab a new image of the cleared section

CIM LineClear guides operators through the line clearance process by means of a color-coded overview of both automatically cleared sections, manually cleared sections and failed inspections.

CIM LineClear takes proven technology to the next level