Turnkey Test Solutions lower Total Cost of Ownership

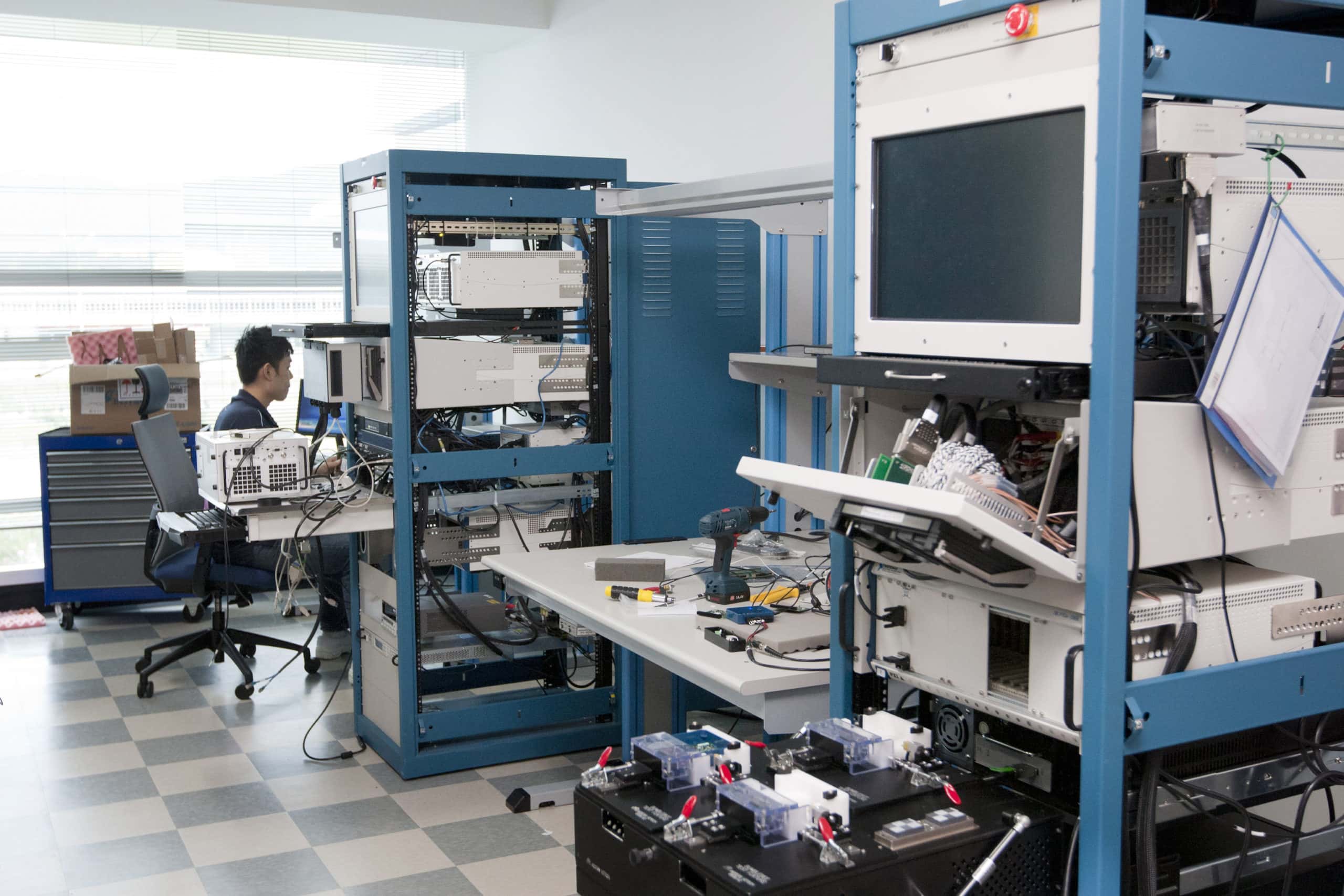

CIM has developed test systems for more than two decades and we work with everything from simple to complex devices, PCBA, final build, off-line and in-line testing. Our main conclusion is this: The more standardized a test system is, the lower the Total Cost of Ownership will be – simply because the Operational Test Costs are reduced during the test system’s lifetime.

Testing adds value and reduces Total Cost of Ownership

We have developed test systems for more than two decades and have worked with everything from simple to complex devices, PCBA, final build, off-line and in-line testing. Our main conclusion is this: The more standardized a test system is, the lower the Total Cost of Ownership will be – simply because the Operational Test Costs are reduced during the test system’s lifetime.

Customized solutions from standardized components

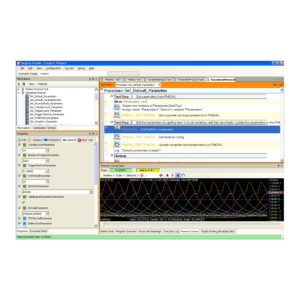

We use flexible, reusable and reliable components when we build a test system. By combining industry standard software (National Instruments LabVIEW and TestStand) with our industry leading software products FlexStand, SeqZap and FACTS, we can develop and commission Automated Test Equipment hardware platforms from companies like National Instruments, 6TLand Keysight. All to meet your budget, technical, and requirement needs.

We start with a test strategy

A test solution from CIM doesn’t just focus on the test specification. We always begin by understanding our customer’s operational requirements – We want to know the expectations to uptime, ease of maintenance, lifetime, etc.

Standardized solutions always win

Standardization means using flexible, re-usable and reliable components built on industry standards. We combine industry standard software like National Instruments LabVIEW and TestStand with our own industry-leading software products to develop and commission Automated Test Equipment. All based on hardware platforms from well-established companies like NI, Keysight and 6TL.

Our products

CIM offers a range of products and solutions within testing – learn more about them below

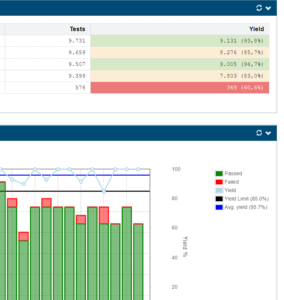

Monitor product quality in all production steps

FACTS is CIM’s Test Data Management system that provides an instant overview of your yield and process data. The easy-to-use web-interface can be accessed from anywhere, and it informs you of key performance and quality indicators like Cp, Cpk, Mean, and Distribution.

This results in a number of benefits:

- Early warnings about production irregularities

- Fact-based feedback to supply chain and production

- Track and monitor process improvements

- Direct production quality measurement using Cpk and Cp values

- Personalized dashboard with drag-and-drop widgets

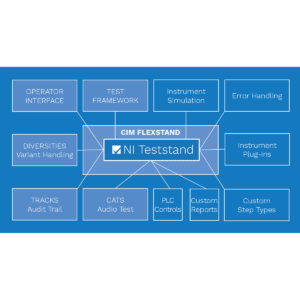

Superior Tools for NI TestStand

As products get more complex, so do the software systems required to test them. Rather than employing/developing device specific code modules and test software, CIM FLEXSTAND for NI TestStand gives you the ability to decouple test features, measurement types and instrument specific drivers from the test sequence. CIM FLEXSTAND for NI TestStand adds functionality out of the box, saving you cost and risk in the test development phase.

Highlights:

- Operator Interface – Build one UI and reuse it for all your test applications

- Audio – Software for production testing of headsets, hearing aids and smart speakers

- Diversities - Product Diversity extended functionality and version control

- Test Framework - Simplify sequencing by using a Test Abstraction Layer

- User Management and Audit trail - Track your changes and user login

The Infrastructure In Your Automated Test System

From Bench Top to Rack Based systems, from Offline to Inline systems, CIM offers yearlong experience in defining the right test platforms for our customer’s needs.

Platform Elements and things to consider

- Power and Safety

- Thermal Profile

- Instrumentation Setup

- Scalability and Standardization

- Lead Time and Global Deployment

CIM work with partners, such as 6TL and NI in defining the best solution for you.

The backbone in Automated Test Systems

Test Instrumentation provides the necessary test and measurement capabilities to and from your device under test. From precise low-voltage measurements to custom digital protocols, ranging from DC to mm Wave, our test instrumentation covers it all. Test instrumentation also includes programmable power supplies, electronic load devices, and other dedicated hardware which should be integrated into the test rack based on the test requirements. Instrument formfactor can be anything from USB to PCI, PXI to YAV to Box Instruments.

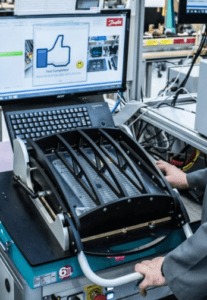

Test Fixtures and Mass Interconnect

Building a test system without a plan for how you will connect your instrumentation to your device under test (DUT) is similar to trying to drive your car without wheels. Your car may have best-in-class horsepower, but you aren’t going to reach your destination without wheels. Mass interconnects and test fixtures are where the rubber meets the road for automated test systems. After determining your instrumentation, the number of switches you need, and the location that your switches will reside in the test system, the next step is to choose a suitable mass interconnect system and design an appropriate fixture that seamlessly connects your DUTs to the rest of the system.

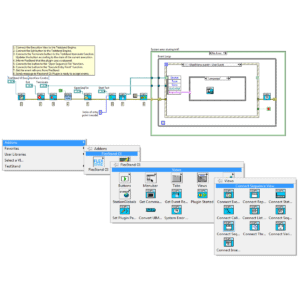

Automate your software test

SEQZAP is CIM's visual software tool for automating tests of software. It is independent of the development process and the current maturity level of your development department – SEQZAP is suited for companies who are new to quality control tools and for those using requirement management tools, test management tools and continuous integration tools.

This results in a number of benefits

- Works with embedded firmware, web apps, and desktop apps

- Easy to use for both software developers and testers

- Requires no programming skills

CASES

Related cases

Case

GN Audio: Efficient audio device test with higher coverage

Case

KK Wind Solutions: Test system increases production capacity

Case

Danfoss: Standardized test solution reduces lifetime costs

Case

Vestfrost: Test system with zero interference despite extreme conditions

Case

Dantherm: Track & Trace system with full ERP integration

References

Don't take our word for it

Christian Wolf

Global Test Manager

GN Audio

Jan Bigum

Lead Engineer

Grundfos Production IT

Michael Bove

KK Wind Solutions

Christhian Cardona

Senior Test Engineer

Danfoss

Contact our specialist in Test

Dennis Morini, Business Development Manager

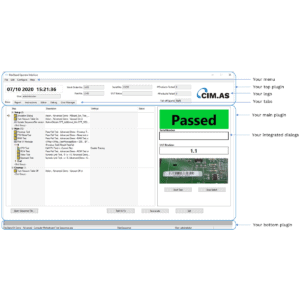

Tired of building one Operator Interface after another for your test station?

We were! So we decided to create a tool for easy development of User Defined Operator Interfaces. We created the FLEXSTAND OPERATOR INTERFACE.

After a short learning curve you can now create you own operator interface for NI TestStand for either Sequential, Batch or Parallel execution.

- Easy and powerfull API for LabVIEW

- Short development time

- Short learning curve

- User defined GUI

- Embedded dialogs

- Automatic resize of plug-ins

- Language control

- Easy deployments

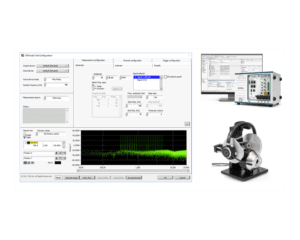

Audio Device Testing software

With todays increasing demands for Personal Audio with new features and technologies, the task of creating an automated test environment for production, is not getting easier. Loudspeakers & Microphones, smart speakers, hearing aids, headphones, headsets and “hearables” are rapidly undergoing design changes, and new features and functionalities are introduced:

• Active Noise Control

• Movement and Bio Sensors

• Wireless connection

• NFC

Just to name a few… This is where CIM FLEXSTAND AUDIO takes over. FLEXSTAND AUDIO is designed for Automated Production Test.

- Signal generation and analysis library

- System calibration

- Analog input and output

- Multiple hardware platforms supported

- Configurable limits

- View live data during test

- Step types for NI TestStand